WOOL PRODUCTION

-

Wool production starts with the shearing of the sheep, which usually happens once a year.

-

A skillful shearer can remove the entire fleece at once with long flowing strokes, keeping the fibers long.

-

After shearing, the wool is washed to remove impurities.

-

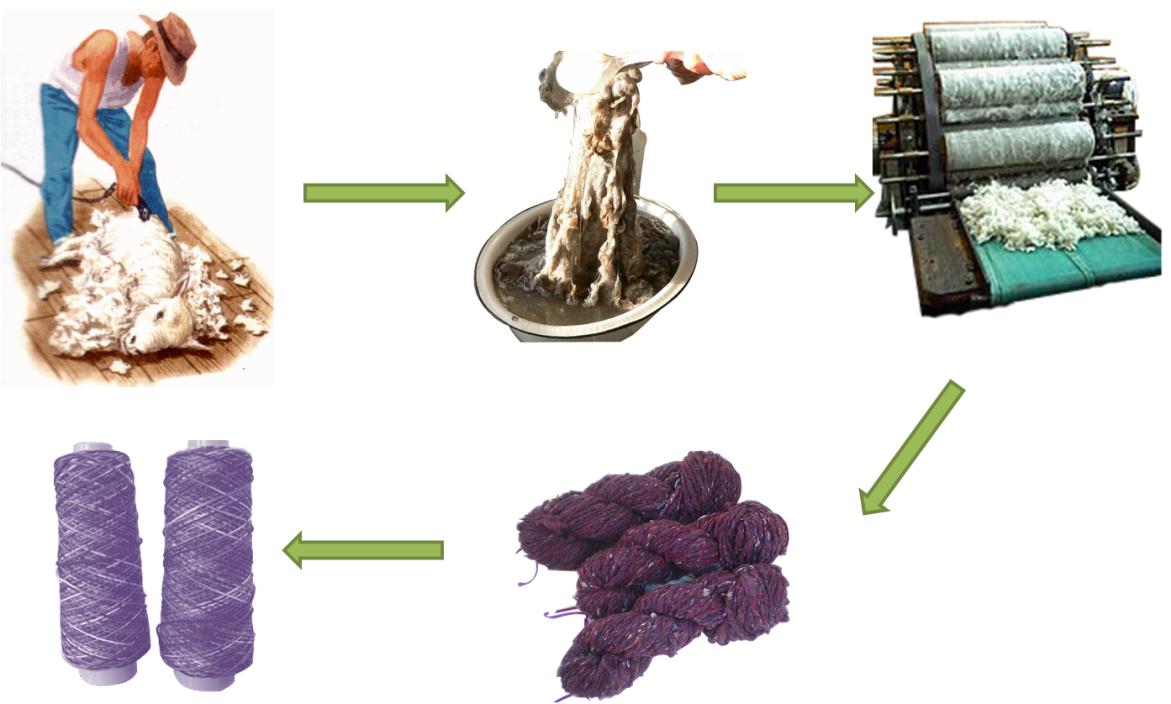

The wool which is used for knitting sweaters or for weaving shawls is the finished product of a long process, which involves certain processes.

-

The different processes involved in wool production are:

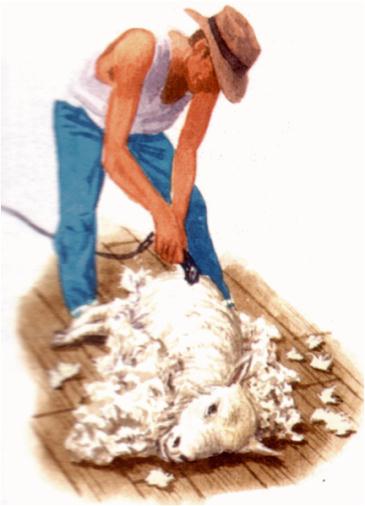

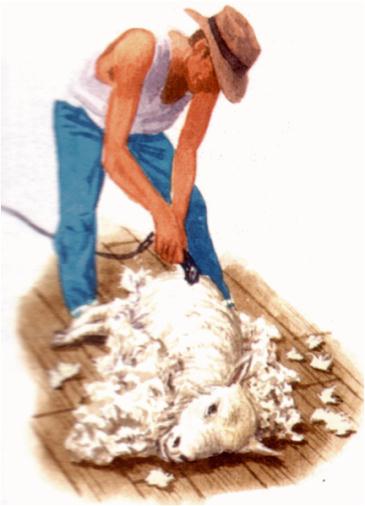

Shearing:

-

The fleece of the sheep along with a thin layer of skin is removed from its body. This process is called shearing.

OR

-

The process of superficial removal of fur from the coat of an animal is called shearing.

-

Sheep are usually shorn annually in the spring/summer months.

-

Shearing is done with a manual razor and blade, or with special clippers.

-

Just like haircuts, shearing does not hurt the sheep it actually helps them by removing the heavy insulating material that they do not require in summer.

-

The shearer tries, as far as possible, to remove the fur in one piece.

-

This enables sheep to survive without their protective coat of hair.

-

The hair provides woollen fibres.

-

Sometimes instead of shearing, fallen or loose hair from the animal's skin are also collected.

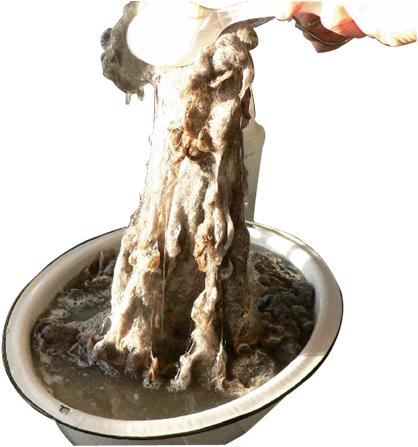

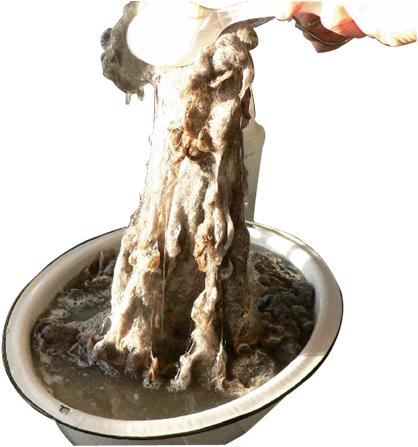

Scouring:

-

The sheared skin with hair is thoroughly washed in tanks to remove grease, dust and dirt. This is called scouring.

Grading:

-

Once the wool has been collected it is graded.

-

This involves grouping and sorting the wool according to its length, colour, texture, and ease of dyeing.

-

The hairy skin is sent to a factory where hair of different textures are separated or sorted.

-

The small fluffy fibres, called burrs, are picked out from the hair.

-

These are the same burrs which sometimes appear on our sweaters.

Dyeing:

-

The fibres can be dyed in various colours, as the natural fleece of sheep and goat is black, brown or white.

Drying :

-

In this process, containers of wool are put through rollers to squeeze out as much water as possible.

-

From the driers, wool is directly sent for binning, where it is weighed and packed into bales.

-

The bales are transported to the mills where they are processed further.

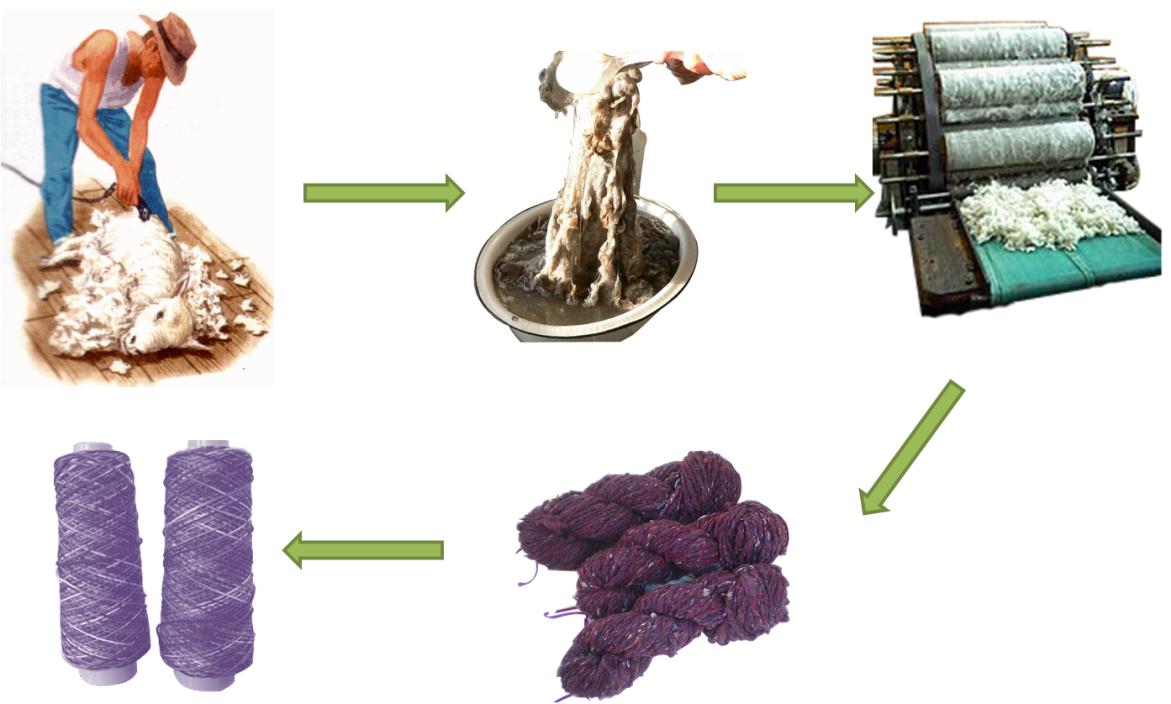

Summary of the process of wool extraction

-

When the fleece is sheared, it is rolled up in bundles sorted out into different qualities or grades, cleaned, stains of various type, dried, entangled fibres are disentangled, twisted and spun in soft, loose irregular thread or yarn.

-

Such strands used together are called 2-ply, 3-ply etc., according to the coarseness or fineness of fabric desired.

-

Carding machine combs the loose wool fibres into a sheet.

-

The sheet is twisted into a rope called 'silver'.

-

The silver is stretched and twisted into a thin yarn.

-

The yarn is wound to form balls of wool.

-

At last, wool may be dyed at the various stages of the manufacturing process. Wool fibre is warmer but coarser than cotton, linen, silk and rayon.

|

FACTS/BRASS TACKS

In 1994, Australian scientists invented a way of removing wool from sheep without shearing.

They inject the sheep with a special hormone, and then wrap them in tight hairnets.

Three weeks later, the fleece can be peeled off. The new wool harvest technology is called Bio-clip.

|

Advantages of Wool:

-

It is easier and quicker to spin wool than cotton or flax.

-

It is warmer.

-

The lanolin on the wool makes it shed water, so it is a good fibre to wear if we are out in the rain.

Occupational Hazard in the Wool Industry:

-

Wool industry is an important means of livelihood for many people in our country.

-

But sorter’s job is risky as sometimes they get infected by a bacterium.